Is Becoming a Welder Worth It? Pros & Cons and Earnings

Is Becoming a Welder Worth It?

Considering this career field, you may wonder if it is worth getting into. Here is what you should know.

Yes, it is worth becoming a welder. The median pay for a welder is $47,540 a year, with a median hourly pay of $22.86 in 2022. The welding industry is projected to grow by 3% between 2020 and 2030, with 42,600 job openings available. These openings will replace many of the retiring people in the industry.

So is becoming a welder worth it? This article covers everything, from getting started as a welder to the pros and cons, salary, and more.

What Does a Welder Do?

Welders are skilled tradespeople who join metal parts together using heat and pressure. They work with various materials, including steel, aluminum, and copper, and use various welding techniques, such as MIG, TIG, and stick welding.

Welders work in various settings, from factories to construction sites, and their work is essential to creating many products and structures.

As a welder, you’ll need to be physically fit, have good hand-eye coordination, and be comfortable working in confined spaces.

You’ll also need to be able to read and interpret blueprints and be familiar with welding safety procedures.

Industries and Sectors for Welders

Welders are in demand across a range of industries and sectors. Here are some of the areas where skilled welders are needed:

- Manufacturing: Welders are needed to create various products, from cars and airplanes to appliances and electronics. In manufacturing, welders work in factories and assembly lines and ensure that products are built to specifications.

- Construction: Welders are needed to build everything from buildings and bridges to pipelines and oil rigs. In construction, welders work on-site and join metal parts to create safe and durable structures.

- Aerospace: Welders are needed to build and maintain aircraft, from commercial airliners to military planes. In aerospace, welders work in factories and repair shops and ensure that aircraft are safe and airworthy.

- Automotive: Welders are needed to build cars, trucks, and other vehicles. In the automotive industry, welders work in factories and assembly lines and ensure that vehicles are built to specifications.

- Agriculture. Welders need to build gates, skid loader buckets, farm equipment, and someone to fix the things that break for farms. These can be welders who build this equipment or go on-site to fix or build things.

Welders are in demand across various industries and can earn a good salary with opportunities for advancement and specialized training.

Becoming a Welder: The Process

If you are interested in becoming a welder, there are several steps you need to take to enter this profession.

In this section, I will outline the education and training requirements you need to meet, as well as the apprenticeship and on-the-job training you will need to undergo.

Education and Training Requirements

To get a weld job at most businesses, you must have a high school diploma or GED. While a high school diploma is not always required, it is highly recommended.

You may also want to attend a welding or vocational school to gain the necessary skills. These schools offer certificate and diploma programs in welding that typically last from a few months to a year.

This isn’t required to become a welder, but it can provide a well-rounded education if you’re new to the field.

Hobart Welding School is a great place to get started. They have a 40-week program that can teach everything from core training and pipe fitting to welding fabrication.

During your training, you will learn about welding safety, welding techniques, and the different types of welding equipment. You will also learn to read blueprints and use welding tools and equipment.

Finally, you’ll learn specific techniques, such as pipe fitting and manufacturing, as well as various types of welding, including gas metal arc, shielded metal arc, and oxyacetylene welding, among others.

Apprenticeship and On-the-Job Training

After completing your education and training, you must undergo an apprenticeship or on-the-job training. This will allow you to gain practical experience and learn from experienced welders.

Apprenticeships typically last 3 to 5 years and involve classroom instruction and on-the-job training.

During your apprenticeship, you will work under the supervision of a skilled welder and learn about different welding techniques and equipment.

On-the-job training is another option for gaining practical experience. This involves working as a welder’s helper or assistant and learning on the job.

While on-the-job training does not typically provide as much structured training as an apprenticeship, it can be a good way to gain experience and learn from experienced welders.

Most welding jobs will do on-the-job training provided you have some basic experience and understanding of welding.

Welding Techniques and Specializations

As a welder, I have learned that there are various welding techniques that one can specialize in.

Depending on the job requirements, these techniques are used to join or repair metal using different methods. Here are some common welding techniques:

Common Welding Techniques

- MIG Welding: MIG (Metal Inert Gas) welding is a popular technique that uses a wire electrode to weld metal. It is commonly used in the automotive industry due to its speed and ease of use.

- TIG Welding: TIG (Tungsten Inert Gas) welding is another popular technique that uses a tungsten electrode to weld the metal. It is commonly used in aerospace due to its precision and high-quality welds.

- Arc Welding: Arc welding is a welding technique that uses an electric arc to weld metal. It is commonly used in construction and manufacturing due to its versatility and ability to weld thick metals.

Specializations in Welding

Apart from these common welding techniques, there are several specializations in welding that one can pursue. Here are some of the specializations:

- Underwater Welding: Underwater welding is a specialized welding technique that involves welding underwater. It is commonly used in the oil and gas industry for repairing offshore rigs and pipelines.

- Pipe Welding: Pipe welding is a specialized welding technique that involves welding pipes. It is commonly used in the construction industry for building pipelines, plumbing, and HVAC systems.

- Structural Welding: Structural welding is a specialized technique that involves welding structural steel. It is commonly used in the construction industry for building bridges, buildings, and other structures.

Skills and Attributes of a Successful Welder

As a professional welder, I have found that certain skills and attributes are essential for success.

These skills can be divided into technical skills and personal attributes.

Technical Skills

To become a successful welder, you must possess various technical skills. Some of the most important technical skills include:

- Manual dexterity: Welding requires a high level of manual dexterity. You must be able to manipulate tools and materials with precision and accuracy.

- Stamina: Welding can be physically demanding work. You must have the stamina to work for long periods without getting fatigued.

- Attention to detail: Welding requires a high degree of precision. You must be able to pay close attention to detail and ensure that your work is of the highest quality.

- Organization: Welding involves working with a variety of tools and materials. You must keep your workspace organized and have all the necessary tools and materials to complete your work.

Personal Attributes

In addition to technical skills, certain personal attributes are essential for success as a welder. Some of the most important personal attributes include:

- Experience: Welding is a skill that is developed over time. The more experience you have, the better you will become at welding.

- Skillset: A successful welder must possess a diverse skillset. This includes welding skills and skills in math and spatial reasoning.

- Dexterity: Besides manual dexterity, a successful welder must possess mental dexterity. You must be able to think quickly and adapt to changing situations.

Career Progression and Advancements in Welding

As a welder, there are various career progression opportunities available. In this section, I will discuss the different career paths and specializations a welder can take to advance their career.

Career Ladder in Welding

Welding offers a clear career ladder, starting with entry-level positions and progressing to more advanced roles.

- The first step is to complete a welding program or apprenticeship, which provides the necessary skills and knowledge to start working as a welder.

- After gaining some experience, welders can become journeyman welders, a certification level that recognizes their proficiency in welding techniques.

- From there, welders can progress to become welding inspectors, which involves ensuring that welding work meets safety and quality standards. Welding inspectors are responsible for examining welds and performing tests to ensure they meet industry standards.

Types of Welding Certifications

Welders can also obtain additional certifications to demonstrate their proficiency in specific welding techniques or materials.

The American Welding Society offers certifications in various welding techniques and materials, such as aluminum and stainless steel.

Below are the different types of certifications you can get.

Certified Welding Inspector (CWI)

A Certified Welding Inspector (CWI) ensures the quality and integrity of welds in various industries by examining and assessing welding procedures, materials, and workmanship according to established standards and codes.

CWIs are crucial in maintaining safety and compliance with industry regulations, certifying that welded structures meet the required quality standards.

Senior Certified Welding Inspector (SCWI)

A Senior Certified Welding Inspector (SCWI) is an advanced-level welding inspection professional with extensive experience and expertise.

SCWIs oversee and manage complex welding projects, conduct advanced inspections, and provide leadership in ensuring compliance with industry standards, promoting safety, and maintaining high-quality welding practices.

Certified Welding Supervisor (CWS)

A Certified Welding Supervisor (CWS) is a skilled professional supervising and coordinating welding activities within a manufacturing or construction setting.

CWSs ensure welding operations adhere to industry standards, safety protocols, and project specifications, contributing to welding projects’ efficient and high-quality completion.

Certified Welding Educator (CWE)

A Certified Welding Educator (CWE) is an experienced and qualified professional specializing in teaching and training individuals in the art and science of welding.

CWEs play a crucial role in imparting essential knowledge, skills, and safety practices to aspiring welders, contributing to developing a competent workforce in the welding industry.

Certified Welding Engineer (CWENG)

A Certified Welding Engineer (CWENG) is a highly skilled professional with specialized knowledge in welding engineering, materials science, and design principles.

CWENGs oversee and optimize welding processes, ensure structural integrity, and provide expertise in developing and implementing welding procedures to meet industry standards and project requirements.

Certified Resistance Welding Technician (CRWT)

A Certified Resistance Welding Technician (CRWT) is a trained specialist with expertise in resistance welding processes, techniques, and equipment.

CRWTs play a crucial role in ensuring the efficiency and quality of resistance welding operations by inspecting, troubleshooting, and maintaining equipment and implementing proper procedures to achieve reliable and consistent welds.

Certified Radiographic Interpreter (CRI)

A Certified Radiographic Interpreter (CRI) is a professional skilled in interpreting radiographic images to evaluate the quality and integrity of welds in various industries.

CRIs ensure welds meet specified standards and codes by carefully analyzing X-rays or other radiographic images for any defects or inconsistencies in the welding process.

Certified Robotic Arc Welding (CRAW)

Certified Robotic Arc Welding (CRAW) is a specialized certification for professionals with expertise in programming, operating, and maintaining robotic systems used in arc welding applications.

Individuals holding the CRAW certification demonstrate proficiency in harnessing robotic technology to perform precise and efficient welding tasks, contributing to the automation and optimization of welding processes in various industrial settings.

Certified Welding Sales Representative (CWSR)

A Certified Welding Sales Representative (CWSR) is a welding industry professional with expertise in welding processes and sales techniques.

CWSRs are responsible for promoting and selling welding-related products and services, often liaising between customers and manufacturers to ensure the appropriate selection and application of welding equipment and consumables.

Certified Associate Welding Inspector (CAWI)

A Certified Associate Welding Inspector (CAWI) is an entry-level professional in the field of welding inspection who works under the supervision of a Certified Welding Inspector (CWI).

CAWIs assist in conducting inspections, ensuring that welding activities comply with industry standards, and contribute to maintaining the quality and integrity of welded structures.

The Demand and Job Opportunities for Welders

Current Job Market

As of today, the job market for welders is strong. And companies are actively looking for more welders. Even though the industry’s growth has slowed, more welders will always be needed.

Welders can earn a good salary with opportunities for advancement and specialized training. The manufacturing and construction industries are two major industries with a high demand for welders.

According to indeed.com, the welding industry provides opportunities in various fields, such as aerospace, automotive, aviation, construction, and manufacturing. This diversity in job options allows for flexibility and variety in the welding career path.

Future Prospects

The prospects for welding jobs are also promising. The projected growth rate for employment of welders from 2021 to 2031 is slower than the average for all occupations.

There is still a projected growth of 2%, with an increase of 25,910 welders, according to yeswelder.com. This projected growth indicates that the demand for welders will continue to be strong in the coming years.

Moreover, the welding industry is constantly evolving and adapting to new technologies, which opens up new opportunities for welders. According to tws.edu, welders can enjoy a fulfilling career with relative job security, opportunities to travel, and the ability to start their own business.

Welding Certifications and Their Importance

As a certified welder, I can attest to the importance of proper certifications. Welding is a highly technical skill; certification proves your expertise and opens more job opportunities.

In this section, I’ll discuss the types of welding certifications available and the benefits of being certified.

Benefits of Being a Certified Welder

Being a certified welder has many benefits.

- First, it demonstrates your expertise and knowledge in welding. This can lead to more job opportunities and higher pay.

- Second, certified welders are also more attractive to employers because they have proven their skills through rigorous testing. This can lead to job security and advancement opportunities.

- Third, certification ensures you follow industry standards and best practices. This can lead to safer working conditions and better-quality products.

Pros and Cons of a Welding Career

Benefits of a Career in Welding

As a welder, I can attest to the many benefits of this career

1. Job Security

One of the most significant benefits is job security. Welding is an essential skill in high demand across many industries, including construction, manufacturing, and transportation.

According to the US Bureau of Labor Statistics, the employment of welders, cutters, solderers, and brazers is projected to grow by 3% from 2020 to 2030, as fast as the average for all occupations.

This indicates that skilled welders are always in demand.

2. No College Degree Required

Another advantage of being a welder is the easy entry into the profession. Unlike many other careers, you do not need a college degree to become a welder.

You can enter the welding industry and become a certified welder even if you don’t have formal education or experience.

Many prospective welders start by enrolling in a vocational/trade school or an apprenticeship program with a master welder.

This makes welding a great option for those who want to start working and earning a good salary quickly.

3. Flexibility

Welding is also a career that offers flexibility. Welders can work in various industries, such as construction, manufacturing, and underwater welding.

Welders can also work in different environments, such as indoors or outdoors, and can work full-time or part-time. This flexibility allows welders to find a work-life balance that suits their needs.

Challenges in Welding

While welding has many benefits, there are also some challenges to consider.

1. Physically Demanding

One of the most significant challenges is that welding is physically demanding. Welders often work in uncomfortable positions, lift heavy equipment, and work in extreme temperatures.

This can lead to physical strain and injury, so taking proper safety precautions and using the right protective gear is essential.

2. Safety

Another challenge is that welding can be dangerous if proper safety measures are not followed.

Welders work with high temperatures and dangerous equipment, so following safety protocols is crucial to prevent accidents and injuries.

I’ve seen welders make bad choices, from catching on fire to dropping a steel load off a tow motor. You need to keep safety in mind, or someone could get hurt.

3. Health Concerns

Welders must also be aware of the potential health hazards, such as exposure to fumes and radiation. Proper ventilation and protective gear are necessary to minimize these risks.

You want to protect your eyes, face, and skin when welding. I’ve burnt my eyes welding, and it’s not a great feeling. It feels like hot sand in your eyes.

Fumes from welding certain things, like galvanized or stainless steel metal, can make you sick. When it comes down to it, it’s all about learning the proper safety precautions so you don’t get hurt.

Salary and Compensation for Welders

As a welder, compensation is a major factor when deciding if this career path is worth it. Welding jobs can provide good salaries and opportunities for advancement.

According to the Bureau of Labor Statistics (BLS), the median annual salary for a welder as of May 2022 was $47,540. However, the top 10% of earners in this field made more than $68,750 annually, while the lowest 10% made around $35,380.

Entry-Level Salary

For entry-level welders with little experience, the average hourly wage is around $17.00 to $33.00 per hour.

However, this can vary depending on the type of welding job, location, and employer.

Some entry-level welders may start making less than the average wage, but with experience and skill development, they can increase their earning potential.

Experienced Welder Salary

Experienced welders can expect to earn a higher salary compared to entry-level welders.

Here is how much you could expect to earn based on your experience, according to PayScale.

- Less than one year of experience earns around $17.28/hour.

- 1 to 4 years of experience earns around $19.26/hour.

- 5 to 9 years of experience earns around $21.29/hour.

- 10 to 19 years of experience earns around $22.87/hour.

- 20+ years of experience earns around $24.23/hour.

However, this also doesn’t cover other ways welders earn an income. This would include bonuses, profit sharing, retirement plans like 401k’s, and medical, dental, and vision insurance benefits.

How Much Are Current Welding Employers Paying

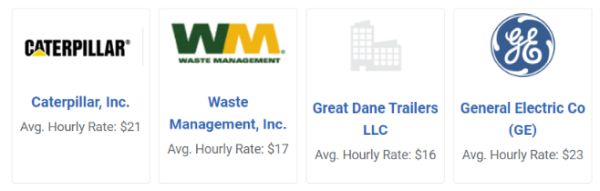

Finally, look at what some current employers pay for welding jobs.

As you can see, companies like CATERPILLAR are paying $21 an hour, Waste Management is paying $17 an hour, and General Electric is paying $23.

Take time to research the company you want to work for. Don’t look at just what they are paying per hour but the whole package, from benefits and work conditions to the people you’re working for.

For example, some companies can pay very well, but if the work environment is less than par and they work a lot of overtime, you have to consider how much stress the job might have.

On the other hand, you might find another company that pays less, but the work environment is less stressful, the boss gives you more leeway, and they let you work four 10-hour work days and have three-day weekends.

So consider all the factors, and you’ll likely land the welding job that’s right for you.

Frequently Asked Questions

What are the benefits of being a welder?

As a welder, you can enjoy the satisfaction of creating something with your own hands. Welding is a skilled trade that requires precision, patience, and attention to detail. Welders can work in various industries, including construction, manufacturing, and automotive repair. Welding is also a career that offers good pay and benefits, especially for those with experience and certification.

Is being a welder a good career choice?

Yes, being a welder is a good career choice for those who enjoy working with their hands, have good hand-eye coordination, and are comfortable working in various settings. Welding is a skilled trade that requires training and experience, but it can be a rewarding career with good pay and benefits. Welders are in demand in many industries, and there is an opportunity for advancement and career growth.

Is it worth getting into welding?

Yes, welding can be worth it for those interested in the trade and willing to put in the time and effort to learn the skills. Welding can offer a stable and rewarding career with good pay and benefits. Welders are in demand in many industries, and there is an opportunity for advancement and career growth. However, it is important to consider the physical demands of the job and the potential hazards of working with hot metals and gases.

What are the disadvantages of being a welder?

One of the main disadvantages of being a welder is the potential hazards of working with hot metals and gases. Welders must wear protective gear and take safety precautions to avoid burns, eye damage, and respiratory problems. Welding can also be physically demanding, requiring strength and stamina to work in awkward positions and lift heavy materials. Additionally, welding can be noisy and dirty, and may involve working in extreme temperatures and weather conditions.

Are welders in demand?

Yes, welders are in demand in many industries, including construction, manufacturing, and automotive repair. According to the U.S. Bureau of Labor Statistics, the employment of welders, cutters, solderers, and brazers is projected to grow 3 percent from 2020 to 2030, about as fast as the average for all occupations. Welders with experience and certification may have the best job prospects.

How to become a welder?

To become a welder, you can start by completing a welding program at a vocational school or community college. Some employers may offer on-the-job training or apprenticeships for those without formal training. Welders can also earn certification from organizations such as the American Welding Society, which can improve job prospects and earning potential. Gaining experience and learning new techniques and technologies is important to stay competitive.